Struggling to protect your wiring from damage? lemore Heat shrink tubing offers a simple, professional solution for insulating and sealing your electrical connections.

Heat shrink tubing is a plastic sleeve that shrinks when heated to fit snugly over wires and components. It provides electrical insulation, protection from moisture and abrasion, and strain relief for cable connections.

Heat Shrink Tubing on Wires

Heat Shrink Tubing on Wires

You might think all tubing is the same, but there’s more to it than meets the eye. Knowing the details can save you from costly failures. Let’s explore what makes this simple product so essential.

How to Choose the Right Heat Shrink Tubing?

Are you worried about picking the wrong size or material? Choosing incorrectly can leave your connections vulnerable and lead to system failures.

To choose the right heat shrink tubing, consider the shrink ratio, diameter, wall thickness, and material. Match these specifications to your wire size and the environmental conditions the connection will face.

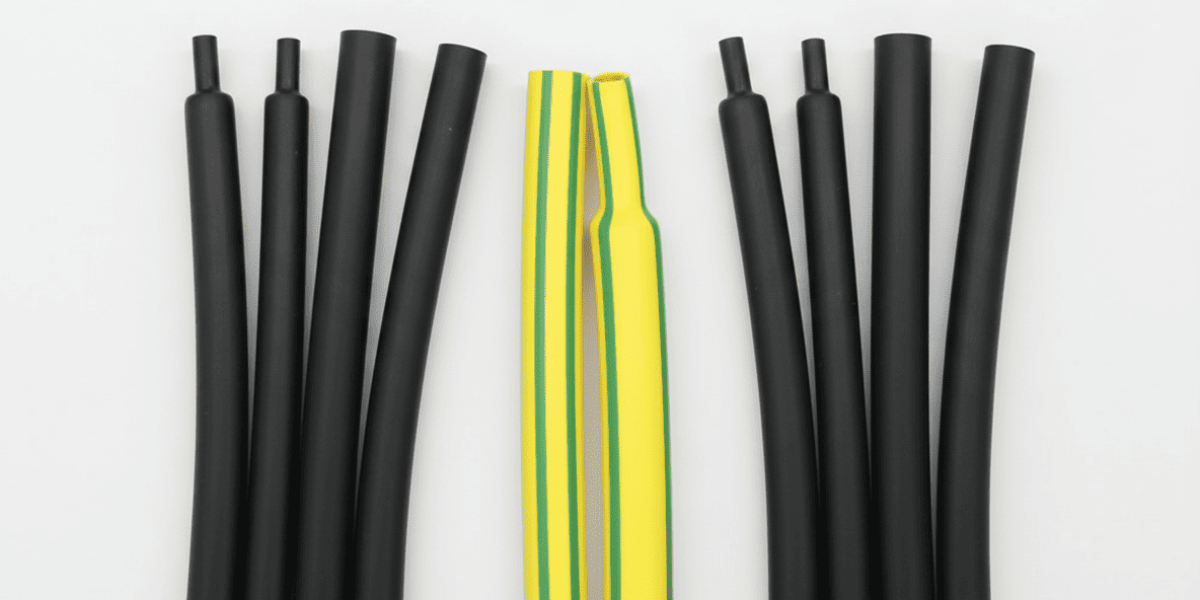

Various heat shrink tubes

Various heat shrink tubes

Selecting the right tubing is crucial for a reliable connection. Here is step-by-step guide for your refference to choose heat shrinkable tubing.

Step1, look at the shrink ratio1, like 2:1 or 3:1. A 3:1 ratio means the tubing shrinks to one-third of its original diameter, which is great for covering irregularly shaped connectors. Next, measure the diameter of your wire bundle. Your tubing’s original diameter must be large enough to slide over it, and its shrunken diameter must be small enough to create a tight fit.

Step 2, consider the material. Most tubing is made from Polyolefin (PE) or PVC. I always recommend PE to my customers, like Oscar, who value quality and compliance. PE is more durable and environmentally friendly than PVC, which can become brittle and release harmful chemicals when heated. If applied in high-temperature environment like 200℃, suggest to choose FEP/PTFE/Knar/Silicone Rubber Material.

Step 3, think about wall thickness2 and your application. For basic insulation, thin-wall tubing is fine. But for a truly waterproof and rugged seal, nothing beats adhesive-lined heat shrink tubing. The inner layer of adhesive melts and flows, creating a complete environmental seal that thin-wall tubing just can’t match.

| Feature | Consideration | My Recommendation |

|---|---|---|

| Shrink Ratio | How much the tube shrinks (e.g., 2:1, 3:1) | 3:1 for covering connectors and irregular shapes. |

| Diameter | Must fit over the wire and shrink tightly. | Measure your bundle, then check the tube’s specs. |

| Material | Durability and environmental impact. | Polyolefin (PE) over PVC for better performance. |

| Wall Type | Level of protection needed. | Adhesive-lined for superior waterproofing. |

How Do You Seal Heat Shrink Tubing?

Afraid of applying heat and damaging your wires? Applying heat shrink tubing is a simple process, but doing it correctly ensures a perfect seal.

To seal heat shrink tubing, slide the tube over the connection, then apply even heat with a heat gun. Start from the middle and work your way to the ends until the tubing has fully shrunk and conformed to the shape underneath.

Shrink the heat-shrinkable tubing with heating gun

Shrink the heat-shrinkable tubing with heating gun

The process is straightforward, but technique matters. First, cut a piece of tubing slightly longer than the area you need to cover. This ensures the connection is fully protected. Slide it into place, making sure it’s centered over the splice or component. Now, grab a heat gun3—a lighter or torch is too intense and can burn the tubing and wires.

Set the heat gun to the recommended temperature for your specific tubing. Begin applying heat to the center of the tubing, not the ends. Keep the heat gun moving constantly, rotating around the wire. This prevents hot spots and ensures even shrinking. As you heat it, you will see the tubing start to shrink down tightly. Slowly work your way from the center out to one end, then go back to the center and work your way to the other end. This technique pushes any trapped air out, preventing voids. If you’re using adhesive-lined tubing4, you’ll see the adhesive start to ooze out from the ends. That’s your sign of a perfect, waterproof seal.

What Are the Disadvantages of Heat Shrink Tubing?

Is heat shrink tubing always the perfect solution? While it’s incredibly effective, it’s important to know its limitations before you commit to using it.

The main disadvantages of heat shrink tubing are that it requires a heat source for application, it creates a permanent seal that is difficult to remove without damaging wires, and using the wrong type can lead to failure.

Heat gun next to a wiring harness

Heat gun next to a wiring harness

Let’s be realistic, no product is perfect for every single situation. One key consideration is that heat shrink tubing is a one-time-use product. Once you shrink it, it’s not coming off easily. This is great for creating a permanent, tamper-proof seal, but it’s a drawback if you think you might need to rework the connection later. This is something I always remind my customers about; get the wiring right before you apply the heat.

Another point is the need for a proper heat source. You can’t just use any flame; a dedicated heat gun is necessary to avoid damaging the tubing or the wires underneath. This means it might not be suitable for field repairs where you don’t have access to power. Finally, the success of the application depends entirely on choosing the right product. If you use tubing that isn’t rated for the voltage, temperature, or chemical exposure of the environment, it will fail. This is why working with a knowledgeable supplier like us at Lemore is key to avoiding these potential pitfalls.

Conclusion

Heat shrink tubing is a superior solution for protecting wires. Choosing the right type and applying it correctly ensures a durable, professional, and reliable seal.

-

Understanding shrink ratio helps you select tubing that fits perfectly and protects irregular shapes effectively. ↩

-

Explore how different wall thicknesses impact insulation and protection levels for your connections. ↩

-

Learn more about the proper techniques for using a heat gun to ensure effective heat shrink tubing application. ↩

-

Explore this link to understand the benefits of adhesive-lined tubing for creating waterproof seals in your projects. ↩